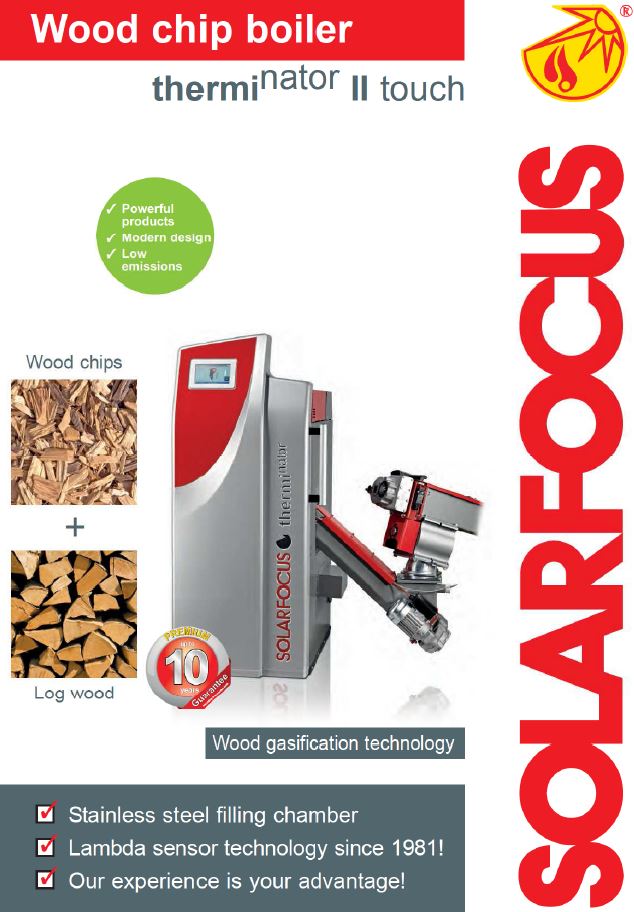

therminator II - wood chip boiler

Perfect wood chip boiler for chip and when you have some logs to burn. Especially when you have some residuales from wood works it makes sense to burn it directly in the log burning chamber.

-

Efficiency of up to 93.3 % with wood chips

Efficiency of up to 94.4 % with log wood -

Intuitive 7" touch display

-

Low-noise – through intelligent geometry and extraction technology

-

Minimum power consumption

Available power ratings:

-

30, 40, 49 and 60 kW

-

Agitator diameter up to 4,0 m

SOPHISTICATED TECHNOLOGY IN DETAIL

TECHNOLOGY and BENEFITS

At first glance, all wood chip boilers are the same. But the difference is in the detail – and that is significant for low-maintenance and reliable operation! The SOLARFOCUS developments are protected by numerous patents. Pioneering technology for your wood chip boiler!

Downfiring combustion technology

-

When using downfiring combustion technology (wood gasification technology) the released gas is sucked through the grate and burned (residue-free) in the combustion chamber with a flame tip temperature of approx. 1,200°C.

-

Efficient fuel utilization

Highest efficiencies

Lambda sensor

-

The Lambda technology, which has been used by SOLARFOCUS since 1981, enables uniform combustion of the pellets in the therminator. Lambda technology is essential to ensure maximum efficiency with different load ranges.

-

Guarantees environmentally-friendly, energy-saving combustion in all load ranges. Decades of experience using Lambda technology.

Automatic ignition / ember retention

-

The boiler ignites the log wood fully automatically via a hot-air fan at the times you set.

-

You can select the "Ember retention" function: Embers then remain in the combustion chamber on the hopper grate for a certain time. This facilitates firing up after a complete burn-out.

Heat exchanger cleaning system

-

“Christmas Tree” Screws clean the walls of the heat exchangers at preset periods. The screws are closely aligned to the heat exchanger walls, removing any residues and depositing them in the ash chamber.

-

AUTOMATIC means AUTOMATIC!

Uniform efficiency saves energy costs! Manual cleaning is not required. Maintenance free.

Generously dimensioned ash chamber

-

Large ash chamber, compressed fireclay bricks.

Easy to replace, no complicated setup work required. -

Lengthens the intervals for emptying of the ash.

Individually mounted fireclay bricks are service-friendly and ensure a long service life for the high-temperature combustion chamber.

Fully automatic cleaning of the stainless steel combustion grate

-

The jogging motor transfers vibrations to the stainless steel combustion grate at adjustable intervals, thus cleaning it fully automatically.

-

Is flange-mounted on the boiler side opposite the ignition fan. The connection is established via the boiler power element.

Flange for wood chip auger

-

Wood chip flange can be mounted on the left or right.

Also available with a blanking flange. -

Allows retrofitting to wood chip operation at any time!

Stainless steel filling chamber

-

The generously dimensioned stainless steel filling chamber is designed to accommodate logs with a length of half a metre (max. 56 cm).

10-year guarantee as per maintenance contract on the filling chamber.

-

Large filling chamber – long burning time.

Secondary air control with servo-motor

-

The lambda-controlled secondary air admixture allows unparalleled combustion quality with highest efficiencies even when burning different biomass fuels.

-

Even in the partial-load range, the boiler remains many times below the emission limit values.

Induced draft fan

-

The combustion air needed in the various areas is sucked in by the speed-controlled induced draft fan. It is controlled by the microprocessor which is built into the control system by the measuring values determined by the lambda sensor.

-

Efficient external rotor motor with stainless steel fan vanes, low noise, maintenance free with speed monitoring.

CROSS-SECTION therminator

A picture is worth a thousand words

Schematic diagram of therminator II touch 40

- Lambda sensor

- Autom. ignition via hot air fan

- Charging door

- Safety temperature limiter (STB)

- ID fan

- Heat exchanger cleaning

- Primary air control

- Grate

- Flange for automatic feeding

(optionally either left or right) - Funnel grate

- Generous ash chamber

- Back-up battery

- Secondary air control with servomotor

- Fully automatic cleaning of the stainless steel grate

- Stainless steel filling chamber

- Control ecomanager-touch

- Fly ash box

THE HEART OF YOUR NEW HEATING SYSTEM

The intelligent boiler control ecomanager-touch

To meet your daily comfort requirements, control is particularly important. You control when the heating comes on and how warm it should be. Both changing outside temperatures and your own personal living habits are taken into consideration. If the therimnatoris used in combination with a solar system, the burner only starts up when the required heating energy cannot be provided in full by the solar system. This prevents any uneconomical boiler starts.

Heating circuit and buffer charge control

- 1 weather-controlled heating circuit (standard)

Upgradable to up to 8 heating circuits with expansion modules (optional) - 3-point heating curve + heating periods individually adjustable

- 1 buffer charging circuit (standard)

Upgradable to up to 4 buffer tanks with expansion modules (optional)

Control of the solar energy system

- The thermitnatoralso controls your solar energy system!

- Optimum exploitation of solar energy via shared control. The boiler only switches on when the sun does not provide enough energy.

- Up to 2 triple circuits can be controlled.

Also suitable for high-efficiency pumps.

ecomanager-touch for smart phone

- helps you to measure and control your heating system and your the hot water system.

- If the boiler is used in combination with a solar energy system, the burner only starts when the required

heating energy cannot be fully provided by the solar energy system. This prevents any uneconomical boiler starts.

weather man function for highest solar thermal gain

- if the SOLARFOCUS boiler is connected to the internet the weather server will update the boiler controller with weather forecast data.

- through live weather data the controller is able to utilize the solar system as much as possible in order to reduce the pellet consumption and to make the system as profitable as possible.

THE CORRESPONDING STORAGE AND SUPPLY SYSTEM

Individually adaptable to suit your requirements

The agitator diameter can be matched to the specific space requirements from 2 to 4 metres in 1/2-metre steps. The agitator with leaf springs transports the wood chips to the direct extraction auger. The progressive leaf springs guarantee efficient emptying of the wood chip storage area. The heavy-duty gearbox, which was specially developed for wood chips, has an output side braking load of up to 27,000 Nm. It is particularly sturdily built and dust-tight to ensure continuous trouble-free operation.