FWMautark

No need for electricity!

Conventional fresh water modules (FWM) transfer heat from a buffer tank to the tab by flowing through a heat exchanger and this flow is created by an electrical pump.

With the FWMautark, electrical pumping power and regulation is no longer required for DHW preparation. DHW is prepared purely via line pressure, thereby eliminating the need for an electrical pump. When using this brand-new fresh water module, fresh, hot water is always available - storing large amounts of DHW is a thing of the past.

-

Hygienic domestic hot water preparation with flow method

-

No control and sensor technology required

-

No buffer mixing by permanentl

-

No electronic connection required - thereby power saving

Simply ingenious - ingeniously simple

When hot water is tapped, the turbine wheel located in the cold water line starts to rotate. The turbine wheel is directly connected to the pump wheel on the buffer side via a magnetic coupling and pumps the volume flow from the buffer via the heat exchanger. If more hot water is tapped, the turbine wheel also turns faster. This means that a constant hot water temperature can be guaranteed even with different tapped volumes and buffer temperatures, without using electronic control. The desired hot water temperature is set via a thermal mixing valve.

Due to the adjustments of the volume flow from the buffer and the very good heat transfer in the stainless steel plate heat exchanger, the return temperatures into the buffer are very low. This ensures ideal operating conditions for solar systems, heat pumps or condensing boilers. Optimum efficiency is guaranteed.

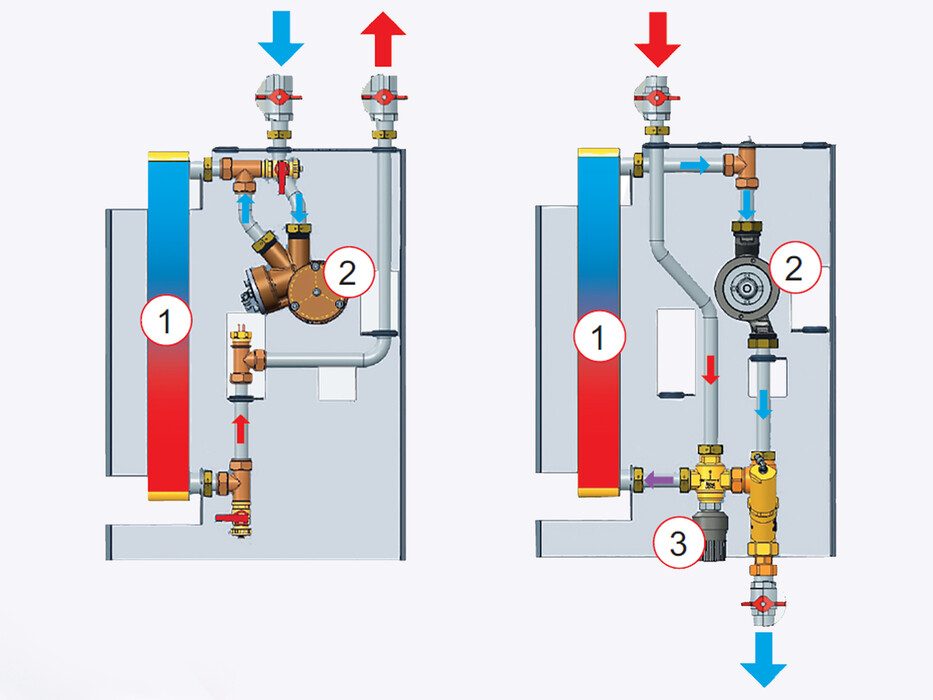

Functional principle

Drinking water side (left picture):

Cold drinking water flows through the turbine wheel (2) and the heat exchanger (1), where it is heated using the countercurrent principle.

Buffer side (right picture):

Hot heating water is transported by the pump (2) to the mixing valve (3). The premixed water flows through the heat exchanger (1) and heats the drinking water in countercurrent.

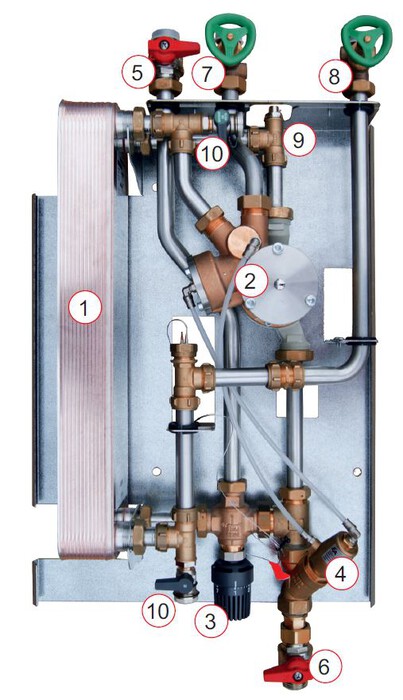

Equipment

- Stainless steel plate heat exchanger

- Cold-water turbine with a flange-mounted heating pump

- Thermal mixing valve to set the hot water temperature

- Hydraulically control non-return valve

- Buffer tank flow 1”OT

- Buffer tank return flow 1”OT

- Cold water input 1”OT

- Hot water output 1“OT

- Ventilation valve

- Rinsing and purging valves, drinking water