pellettop

Proven classic pellet boiler

The biomass boiler is easy to integrate into the heating system of the building. The construction of the boiler is simple and provides easy excess for customer, plumber and service engineer.

The boiler maintaines its high efficiency through the special cleaning mechanism which is fully automatic. However when wood pellets burn there remains always a bit of ash which is stored in the ash box of the pellet boiler. This ash box needs to be emptied usually 4 to 5 times a year.

-

Highest efficiencies provide you a low fuel bill

-

Extremely compact design

-

Intuitive touchscreen boiler control

-

Visualisation on smartphones, PCs and tablet computers

Available power ratings:

- 35, 45, 49 and 70 kW

- Up to 420 kW with cascade connection

SOPHISTICATED TECHNOLOGY IN DETAIL

TECHNOLOGY and BENEFITS

At first glance, all pellet boilers are the same. But the difference is in the detail – and that is significant for low-maintenance and reliable operation! The SOLARFOCUS developments are protected by numerous patents. Pioneering technology for your pellet boiler!

Heat exchanger cleaning system

-

Turbulators clean the walls of the heat exchanger at regular preset intervals. Increased exhaust gas temperature results in a loss of efficiency.

Clean fuel exchangers save fuel! -

AUTOMATIC means AUTOMATIC!

Uniform efficiency saves energy costs! Manual cleaning is not required. Maintenance free.

Auger feeder with single axis rotary valve

-

The pellets are transported from the intermediate container by the feed auger into the single axis rotary valve. The single axis rotary valve hermetically seals-off the combustion chamber from the intermediate container. Six-chamber system - along an axis to the feed auger with a direct flanged-connection, maintenance free drive motor.

-

100% backburn-proof even if there is a power failure. Minimum power consumption. No chains or gear wheels - low noise and maintenance free.

Stainless steel grate and cleaning

-

The pellets fall from above through the single axis rotary valve onto the stainless steel combustion grate. The fire is not disturbed as the pellets feed from ABOVE on the fire-bed, with no mixing of ash and embers with the pellets = best efficiency!

-

The downfiring combustion technology automatically transports the ash downwards into the ash pan. There is no need to use a complicated mechanism to remove the ash.

Induced draft fan

-

The combustion air sucked in is regulated by the ID fan.

-

Efficient external rotor motor with stainless steel fan vanes, low noise, maintenance free with speed monitoring.

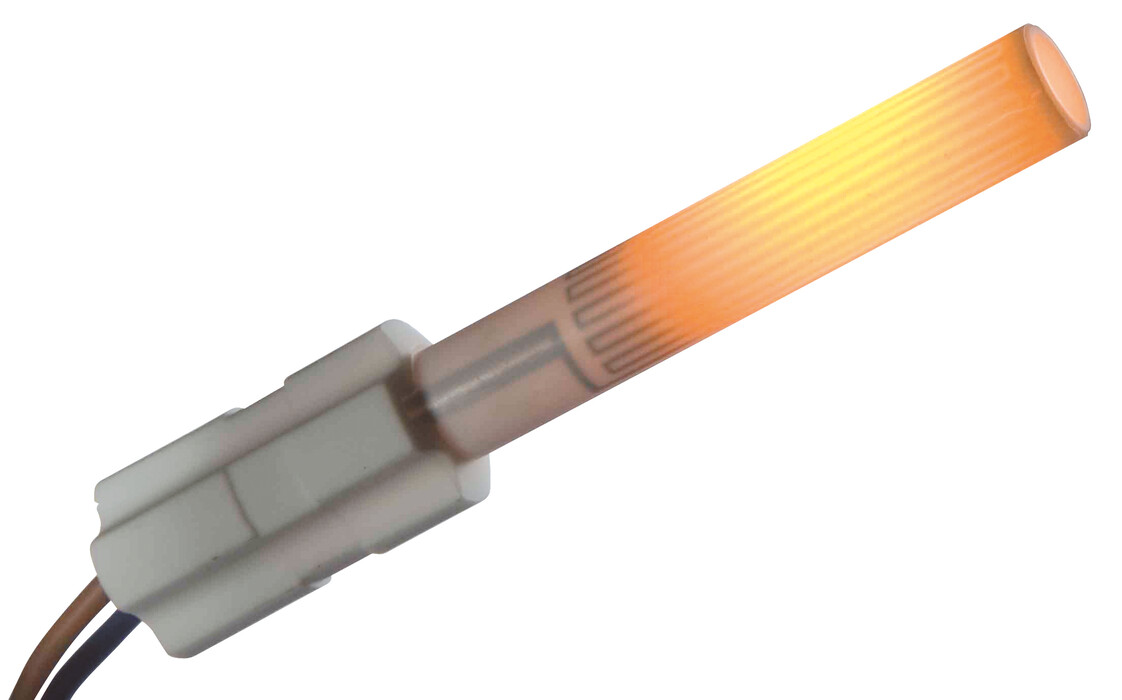

Automatic ignition

- Ignition of the pellets is fully automatic via a highly heat-resistant solid ceramic glow pencil.

- The glow pencil only requires 260 W. The glow pencil operates quietly and is maintenance-free.

Intermediate container for pellets with suction turbine

-

The pellettop has a generous intermediate container. The vacuum system turbine enables filling of the intermediate container within pre-set times in a closed circuit, maintenance free system.

-

The boiler room and pellet storage room do not have to be directly adjacent to each other. The vacuum turbine is directly mounted onto the intermediate container for pellets.

CROSS-SECTION PELLETTOP

A picture is worth a thousand words

Schematic diagram of pellettop 15

- Intermediate container

- Suction turbine

- Pellet auger

- Single axis rotary valve

- Gear drive

- Stainless steel grate

- Automatic ignition

- Downfiring combustion technology / pellets gasification

- Combustion chamber

- Induced draft fan

- Lambda sensor

- Turbolators

- Heat exchanger

- Automatic ash extraction

Schematic diagram of pellettop 70

- Intermediate container

- Suction turbine

- Pellet auger

- Single axis rotary valve

- Gear drive

- Stainless steel grate

- Automatic ignition

- Downfiring combustion technology

- Combustion chamber

- Induced draft fan

- Lambda sonsor

- Turbulators

- Heat exchanger

- Automatic ash removal with ash box

- User-friendly touchscreen control

- Heat exchanger for thermal process safety

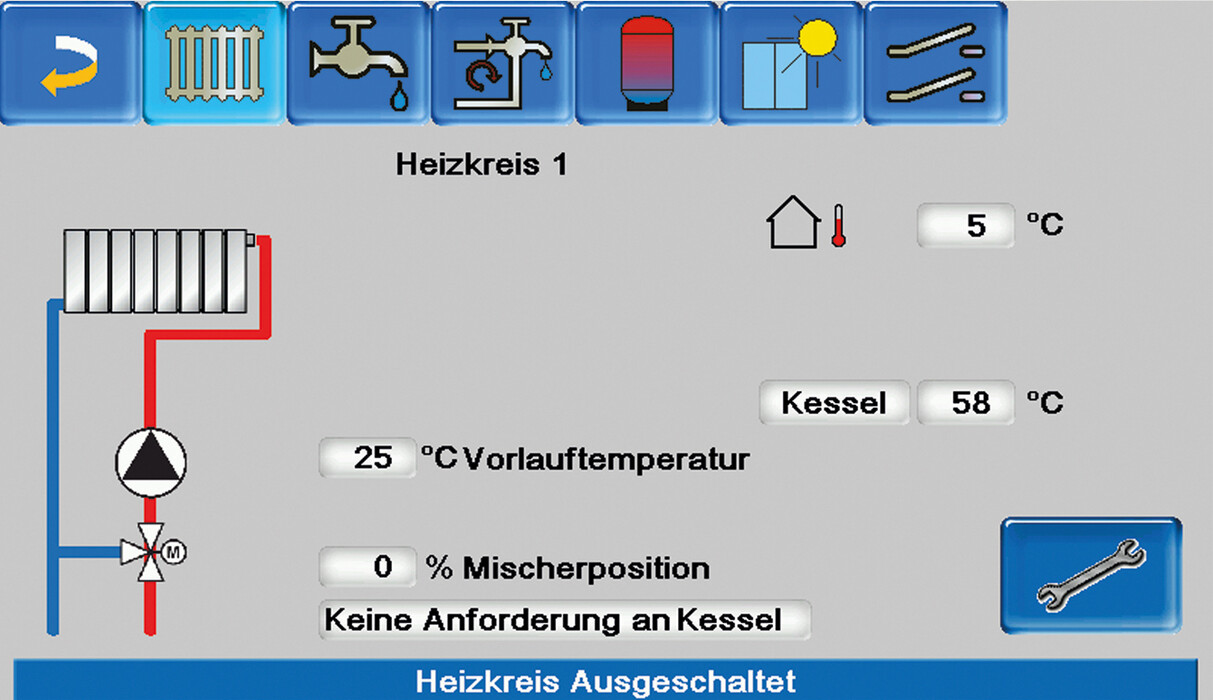

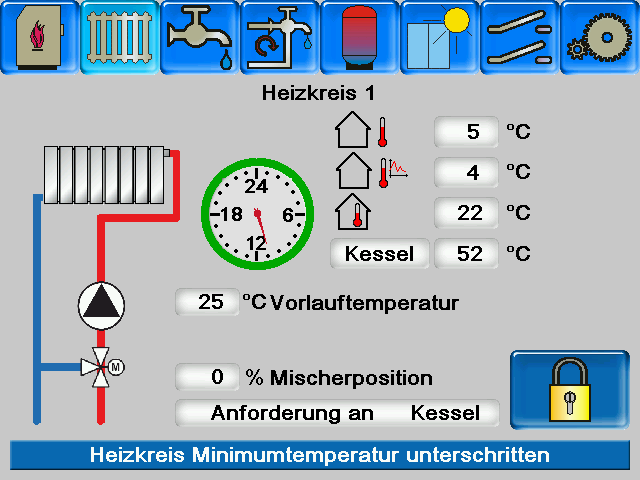

THE HEART OF YOUR NEW HEATING SYSTEM

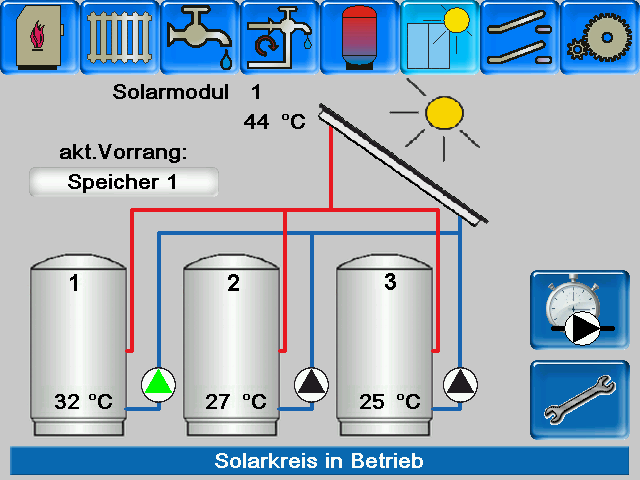

The intelligent boiler control ecomanager-touch

To meet your daily comfort requirements, control is particularly important. You control when the heating comes on and how warm it should be. Both changing outside temperatures and your own personal living habits are taken into consideration. If the pellettop is used in combination with a solar system, the burner only starts up when the required heating energy cannot be provided in full by the solar system. This prevents any uneconomical boiler starts.

Heating circuit and buffer charge control

- 1 weather-controlled heating circuit (standard)

Upgradable to up to 8 heating circuits with expansion modules (optional) - 3-point heating curve + heating periods individually adjustable

- 1 buffer charging circuit (standard)

Upgradable to up to 4 buffer cylinders with expansion modules (optional)

Control of the solar energy system

- The pellettop also controls your solar energy system!

- Optimum exploitation of solar energy via shared control. The boiler only switches on when the sun does not provide enough energy.

- Up to 2 triple circuits can be controlled.

Also suitable for high-efficiency pumps.

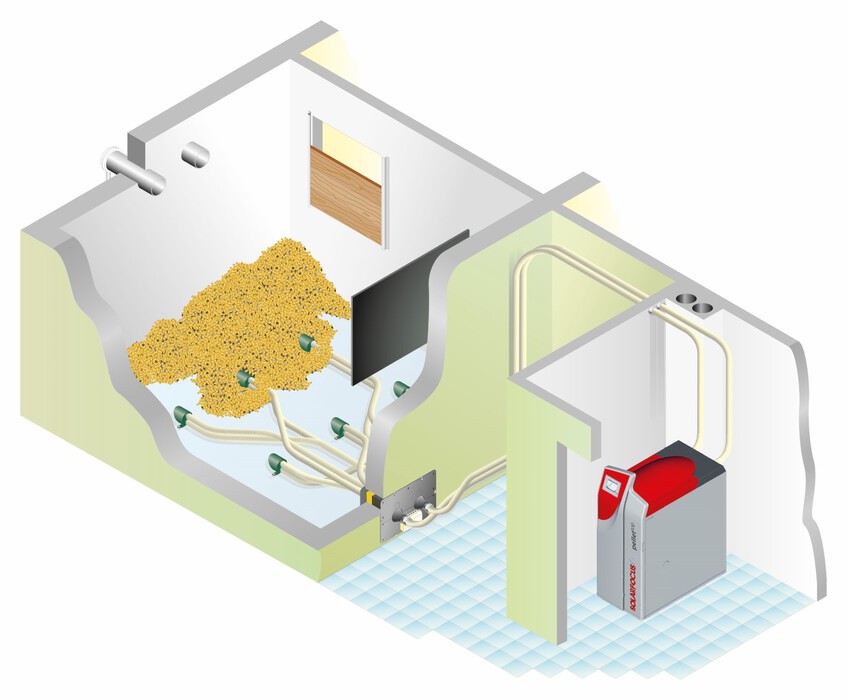

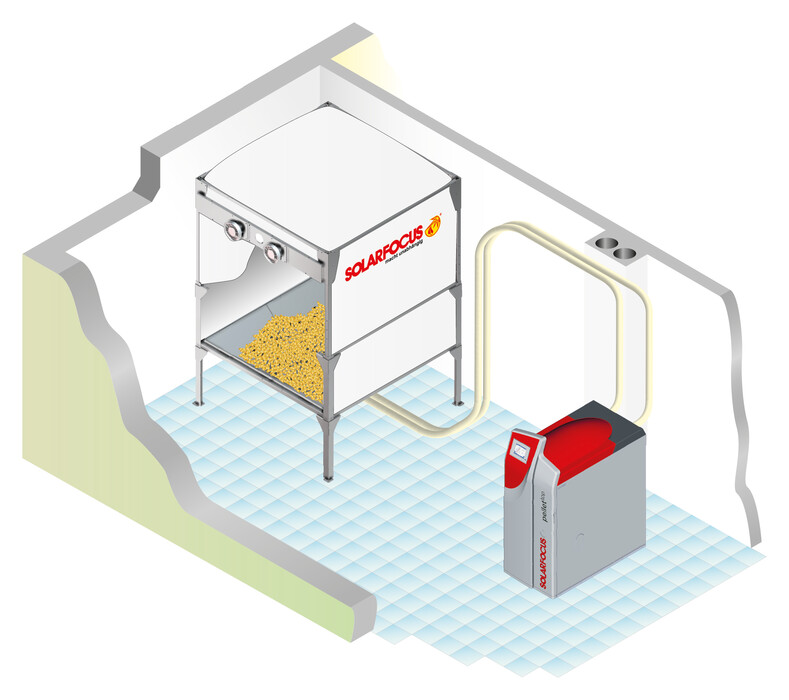

THE CORRESPONDING STORAGE AND SUPPLY SYSTEM

The individual solution for your boiler room

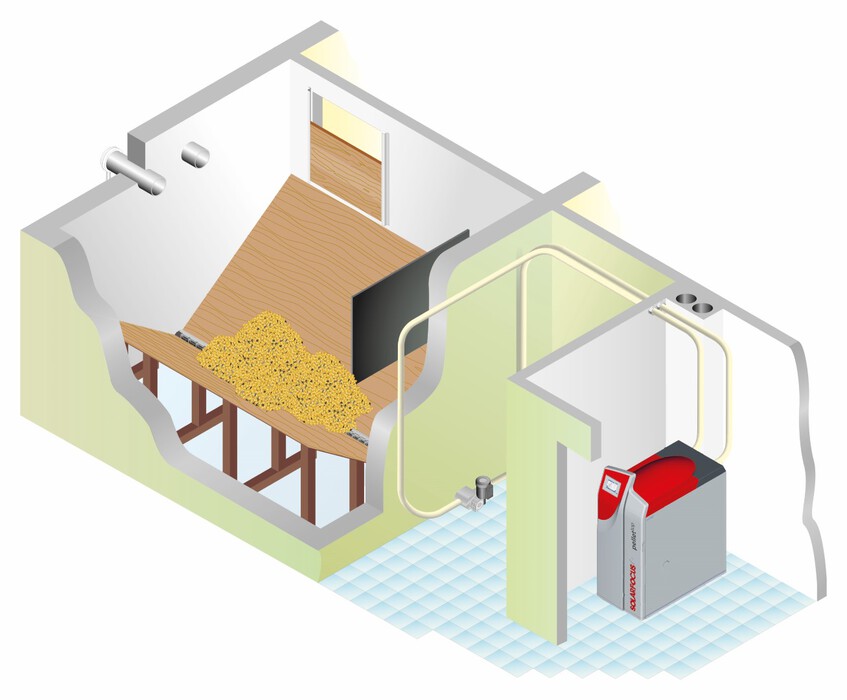

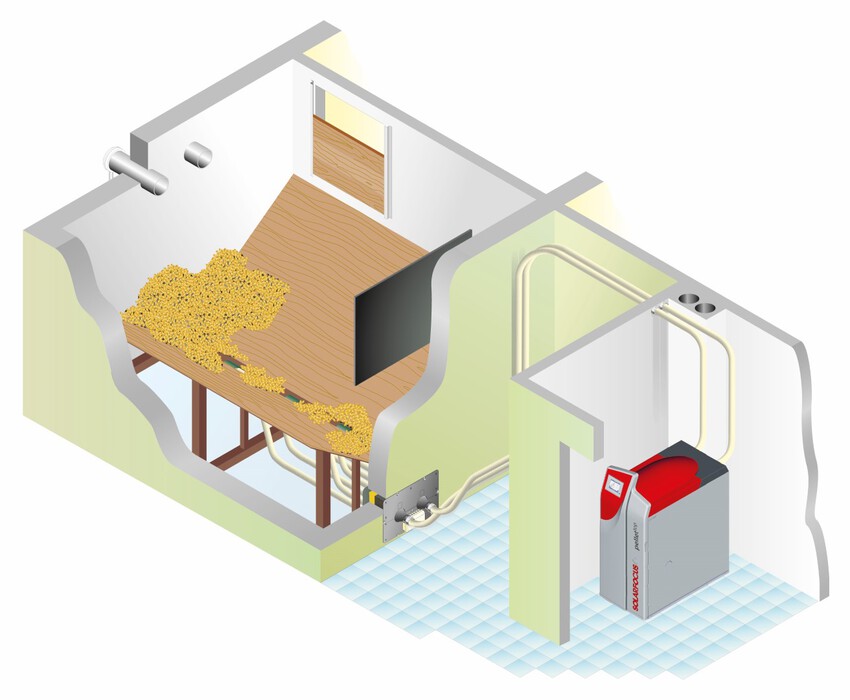

The powerful suction turbine in the boiler transports the pellets from the suction head or from the auger into the integrated intermediate pellet store. The patented single-axis rotary valve ensures adequate metering of the fuel and is 100% burnback-proof. Your SOLARFOCUS heating engineer will be pleased to advise you on-site and help you choose the right storage and supply system.

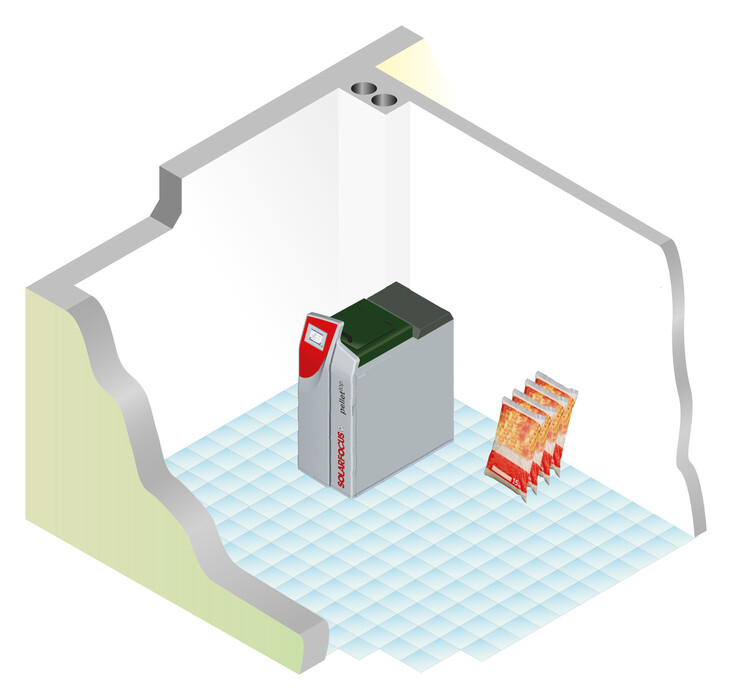

Suction system with suction heads

- Optimum utilisation of the available space, as there is no need for a sloping floor

Also ideal for awkwardly shaped and wide storage areas

Minimum installation effort - Automatic diverter for suction heads with up to 6 suction heads

Manual diverter for suction heads with up to 4 suction heads - Max. conveyor length (suction head - boiler) = 30 m

Max. conveying height (suction head - boiler) = 3.5 m

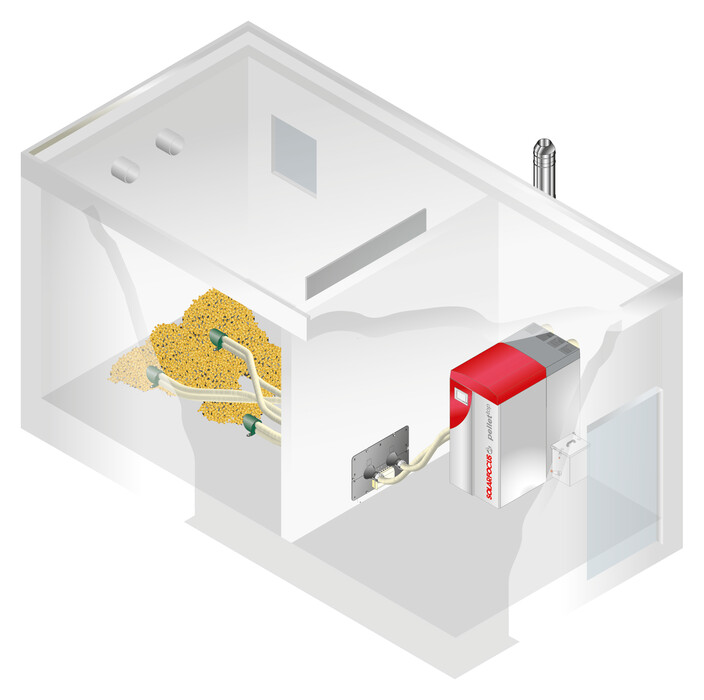

Suction system with suction heads and sloping floor

- Suitable for large, long storage areas

Complete emptying of the storage area - Automatic diverter for suction heads with up to 6 suction heads

Manual diverter for suction heads with up to 4 suction heads - Max. auger length (suction head - boiler) = 15 m

Max. conveying height (suction head - boiler) = 2.5 m

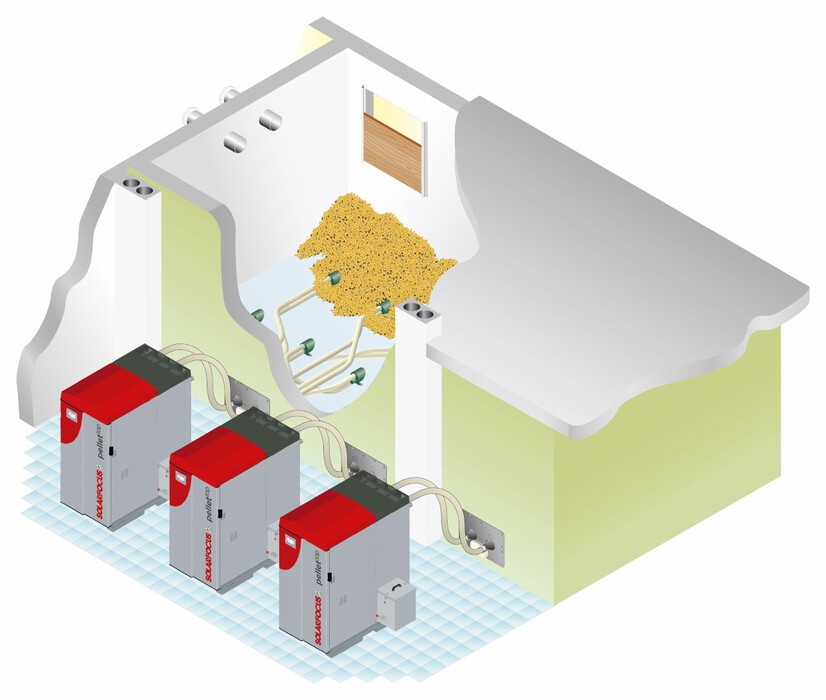

Cascade connection – up to 420 kW

- Ideal for multi-storey residential buildings and commercial premises

- Maximum output is only required for around 10% of the year

Higher efficiency compared to commercial boilers through improved partial-load behaviour - Longer service life through less wear on material

While servicing or maintenance work is being performed on one boiler, the others provide the heat – allowing uninterrupted heating operation